about Us

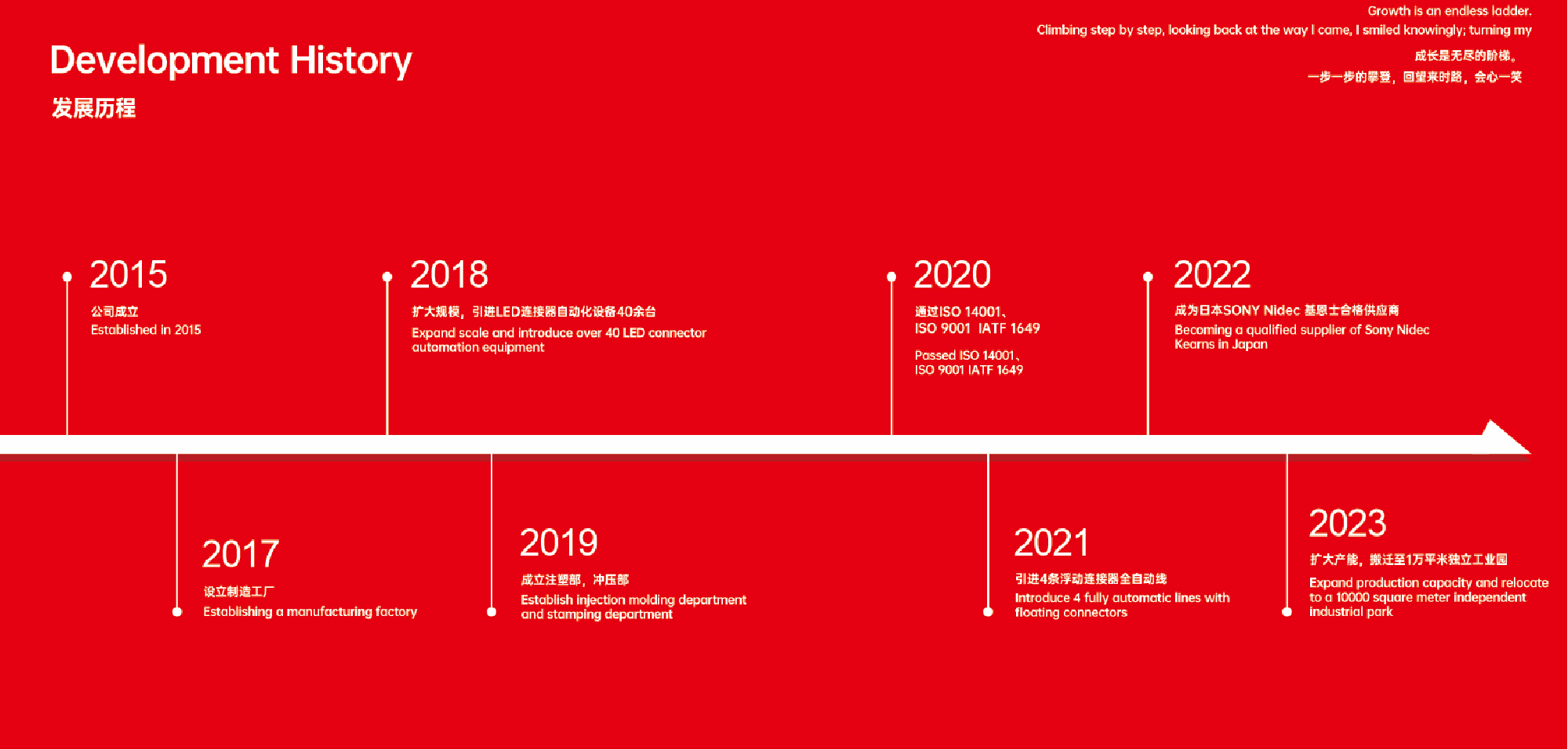

Development course

Our advantages

In the plastic mold design stage,Pro-E software is used for modeling and mold flow analysis software Moldflow is used to analyze the plastic flow direction. Combined with line position, warpage deformation direction and flatness, the design is adjusted to ensure product design quality.

In the early stage of product design, designers use professional spring splinter stress analysis software (ABAQUS) to analyze the maximum stress of the spring splint terminals, predict permanent deformation and positive pressure and adjust the design to the customer's ideal design parameters based on the predicted values to achieve a successful one-time design. The effect is greatly reduced, thereby greatly reducing the possibility of changes after the design is completed, greatly reducing the product design and development cycle, saving product development costs, and making the product more competitive.

SI simulation: Use simulation software and high-performance servers to perform SI simulation on the 3D model of the connector, and optimize the structure when performance is insufficient.

Temperature rise simulation: Use simulation software to simulate the temperature rise of the 3D model of the connector, and optimize the structure when the performance is insufficient.

Quality control

Reflow soldering

Insertion and extraction force test

Pixiv

Current tester

Salt spray tester

Hi-pot Tester

High and low temperature testing

Temperature rise tester

Hardness tester

Environmental tester

lmpedance tester

Film thickness tester

Manufacturing capacity

Mold workshop

Automation workshop two

Automation workshop

Dust-free assembly workshop

Stamping Workshop

Injection molding workshop

Customer service